GC Technical Tip

Level: Basic

Peak Shape Problems: No Peaks

No Peaks - Some or all peaks are missing from the run

How many times have you found that some or all peaks are suddenly missing from the run?

In this month’s GC technical tip, we explore some of the possible causes and solutions to overcome peak disappearance, by evaluating three possible scenarios that should cover all possible real cases.

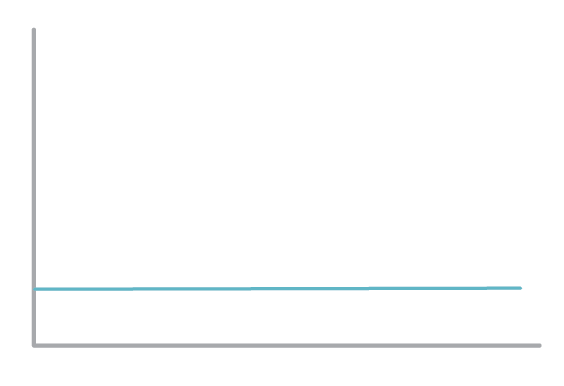

Symptom: All Peaks Missing

| Possible Cause | Suggested Remedy |

|---|---|

| Defective or clogged syringe. | Try a new or proven syringe. |

| “Blown” septum or massive leaks at the inlet. | Find and fix leaks. |

| Problems with carrier gas flow. | Adjust gas flow. |

| Column may be broken or installed in the wrong detector or inlet. | If breakage is close to the beginning or end, cut off the short piece. Breakage in the middle can be repaired with a press-fit connector. For multiple breakages, replace or reinstall the column. See column installation. |

| The detector is not functioning or is not connected to the recorder or integrator. | Ensure detector is working properly. (e.g. is the flame in a FID lit?) Check connection to the output device. |

| Incorrect injector temperature:

| Cold injector: check injector and oven temperature with an accurate thermometer. If accurate, increase temperature as necessary, but do not exceed the maximum temperature limit of the column. Inject the sample directly onto the column.

Hot injector: check injector and oven temperature with an accurate thermometer. If accurate, reduce temperature as necessary, ensuring compatibility with sample and column minimum limit. |

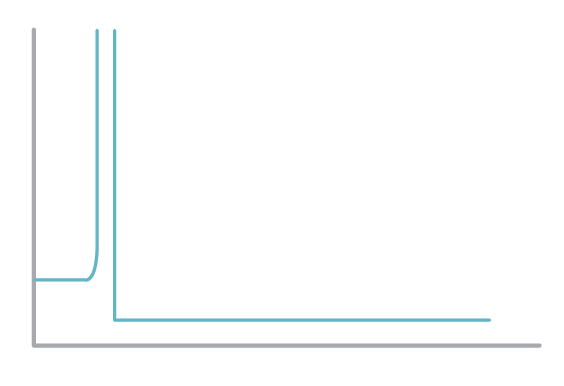

Symptom: No Peaks After Solvent Peak

| Possible Cause | Suggested Remedy |

|---|---|

| Sample volume is too high. | Inject less sample or use a higher split ratio. |

| For FID detectors, the flame is blown out by the solvent peak. | Check the detector temperature. |

| Carrier gas flow is too high. | Reduce the flow rate. |

| Incorrect column temperature; column is too hot and sample is eluting in solvent peak. | Check oven temperature with an accurate thermometer. If accurate, reduce temperature as necessary, ensuring compatibility with sample and column minimum limit. |

| Column cannot separate components from solvent. | Change solvent or column. |

Symptom: Some Peaks Missing

| Possible Cause | Suggested Remedy |

|---|---|

| Activity in the inlet liner or column if the missing peak is an active compound. | Clean or replace the inlet liner. Ensure an inert column is used. If necessary, replace the column. See column installation. |

When some or all peaks are missing in a GC analysis most causes are related to the detector, which plays a crucial role, but do not dismiss other possible causes, such as a defective syringe, an improper injection or an activated column or liner.

See you on the next technical tip, feel free to contact us if you need support in troubleshooting or for your method development.