HPLC/UHPLC Technical Tip

Level: Intermediate

The Benefit of Trapping in Micro and Nano LC

Micro and Nano LC columns offer chromatographers the opportunity to improve sensitivity by using lower flow rates, thanks to their smaller internal diameter (ID), which improve analyte concentration at the detector — especially useful when coupling LC to mass spectrometry (LC–MS). However, working at micro and nano flow rates also introduces practical challenges that are less critical in conventional LC. One of the most commonly used solutions to address these challenges is the use of a trap column.

As column internal diameter and flow rate decrease, chromatographic performance becomes much more sensitive to system configuration. Extra‑column volume from tubing, fittings, or poorly optimized connections can lead to band broadening and loss of efficiency. Hence, zero-dead-volume connectors and small internal diameter tubing (i.e. 25 um for 0.075 and 0.15mm ID columns and 50 um for 0.3-0.5 mm ID columns) are mandatory. Sample loading also becomes more challenging, as injection volumes may be similar to - or even larger than – the column volume. Injecting such volumes directly onto a small column can result in poor peak shape, loss of analyte, or long loading times. In addition, micro and nano LC columns are generally less tolerant of salts, particulates, and other matrix components, often requiring careful sample preparation.

A trap column is designed to address several of these issues at once. It is a short column, placed upstream of the nano/micro LC column and connected through a switching valve, which contains a stationary phase similar or compatible with that of the nano or micro column. During the initial loading step, the sample is delivered to the trap at a relatively high flow rate and under conditions that promote retention of the analytes of interest. While the analytes are retained and concentrated at the front of the trap, most of the sample solvent, salts, and other non‑retained components are flushed to waste. After loading is complete, the valve is switched and the analytes are eluted from the trap onto the micro or nano LC column at a lower flow rate, where chromatographic separation occurs. By rapidly loading and concentrating the sample on the trap, we mitigate analyte loss and peak broadening, while efficiently and effectively transferring the sample onto the column.

Trapping is particularly beneficial in nano LC because the small column volumes make the effects of large sample injections more pronounced. Without trapping, loading even moderate sample volumes can significantly degrade chromatographic performance. By pre‑concentrating analytes on a trap, users can load larger volumes without compromising peak shape or sensitivity. In both micro and nano LC, trapping can also improve robustness by reducing the amount of matrix reaching the nano/micro column and detector, which is especially important in LC–MS workflows.

Trap Elution Configuration

Phase selectivity and the direction of mobile phase flow onto and off the trap column, will all contribute to column efficiency and lifetime. There are two common ways to elute analytes from a trap column: forward elution and backward, or reverse, elution. The choice of an appropriate stationary phase for your trap will help to improve analyte recoveries, whereas direction of flow during your trap and elute method can improve column lifetime.

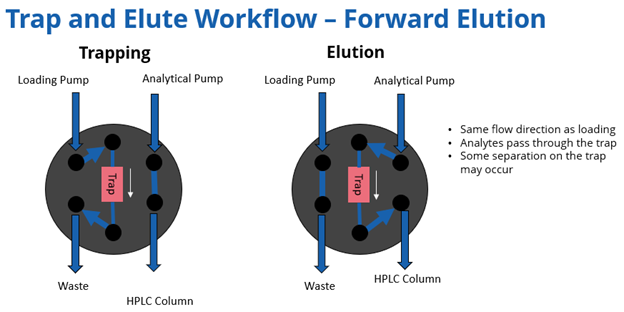

Forward Elution

In forward elution, the sample is first loaded onto the trap in one direction and the analytes are retained at the front of the trap, while salts and other non-retained components of the matrix are washed away. After switching the valve, the flow coming from the low-flow pump enters the trap in the same direction in which we did the loading step (forward direction), making the analytes migrate through the short trapping column and elute out into the micro/nano column. Depending on the length and selectivity of the trap, some dispersion or minor analyte separation may occur. This configuration has the advantage of preventing insoluble particles from reaching the nano/micro column, offering additional protection.

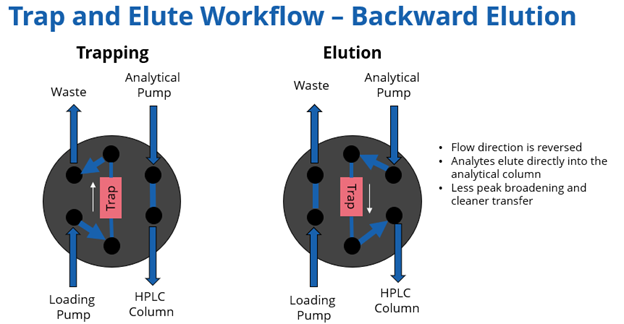

Backward Elution

In backward elution, the sample is loaded and cleaned in the same way as before, but after valve switching, the low-flow gradient is pumped in the reverse direction of the initial loading flow. The analytes are eluted back off the trap and transferred directly to the nano/micro column with minimal migration through the trap length. This approach minimizes peak broadening, rendering the stationary phase less critical in terms of chromatographic selectivity. The main drawback is that any insoluble material retained on the trap can potentially be flushed toward the nano/micro column; hence, sample preparation or inline filtration becomes more important.

In summary, trapping is a powerful and widely used strategy in micro and nano LC that helps overcome challenges related to large sample volumes, matrix effects, and sensitivity. By concentrating analytes and removing unwanted components prior to separation, trap columns can improve chromatographic performance, robustness, and reproducibility. At the same time, the additional hardware and method complexity associated with trapping may not be necessary for very clean samples, small injection volumes, or larger microflow columns, where direct injection can be sufficient.

Live Webinar: Small Scale, Big Impact: Scaling Micro/Nano | 3 or 4 March 2026

Key Learning Points

• Receive an overview of column and method scaling.

• Learn how to scale between analytical and preparative methods.

• Understand how to optimize preparative loading capacity for resolution and yield.

Who Should Attend

Any chemists who work primarily within small-molecule pharmaceutical, university settings, or those working within biopharmaceutical.

Micro LC Columns and Traps Product Brochure

The complete product guide of LC columns and traps for micro LC applications

Phenomenex, the P icon, and the Phenomenex product and service marks mentioned herein are trademarks or registered trademarks of Phenomenex, Inc. in the United States and/or other countries. All other trademarks are the property of their respective owners. One or more authors are affiliated with Phenomenex, Inc. FOR RESEARCH USE ONLY. Not for use in clinical diagnostic procedures. © 2026 Phenomenex, Inc. All rights reserved.