A change in the operating pressure is one the first indications of a problem in chromatographic analysis. Therefore, it is absolutely essential to know what is the normal pressure in relation to your column dimensions, mobile phase composition and flow rate.

Typical back pressure issues can be categorised as, no pressure, low pressure, high pressure and erratic pressure. The LC pump is the source for generating pressure and therefore is also the primary reason for most pressure issues. The more complex reasons for back pressure issues could be one of the following:

- Leakage from the pump seals or somewhere in the flow line

- Blockage in pump capillaries

- Column inlet blocked

- Incorrect solvent choice

- Void in the column

- Air bubbles in the flow line

No and/or high back pressure

Reason: If we leave aside the more trivial issues, the major reason for no pressure or high back pressure will be a blockage either in the column itself or somewhere in the flow line.

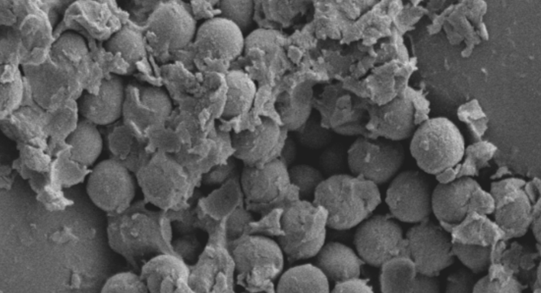

- Inorganic buffer salts are the main culprit in causing these blockages in pump capillaries and column inlets or even inside the pores of the silica sorbent. When used in high concentrations or when the LC system and columns are not cleaned regularly/properly, a blockage can be readily created possibly both in the tubing and column inlet.

- Apart from buffers some analytes or sample matrices can also get accumulated on the column inlets or inside the silica sorbent’s pores and can completely block the column and shut down the flow. One of such analyte/sample is Sugars, especially in high organic conditions in mobile phase sugars can crystallize inside the column pores and have the capacity to completely block the flow from the column.

- Sometimes, extremely non-polar compounds or oily matrices e.g. some cannabinoids, can also strongly or irreversibly bind to the C8 and C18 hydrophobic phases. These fatty oil like substances keep on accumulating onto the column and can eventually result in high back pressures.

- Proteins or few high molecular weight biological compounds can also cause high back pressure or blockages if not removed prior to injection from the sample matrices or if present as an analyte, should be removed afterwards.

Solution: The best way to remove buffer and compounds that can crystallize and be deposited in the capillaries and the pores of the columns, is to clean with HPLC grade water at an elevated temperature.

- Flow rate should almost always be reduced when cleaning your system or column to provide enough time for the wash solvent to either dissolve or interact with the contaminant and get it removed.

- The following flow rates can be used depending on the column IDs:

- For 4.6/4.0mm = 0.5ml/min, 3.0mm = 0.3ml/min, 2.1mm = 0.2ml/min

- Reverse flushing is required to remove the contaminants that might be deposited on column inlet frits. However, there is an absolute condition that should be fulfilled when performing an initial reverse flush in the column, please ensure that you disconnect the detector from the column or else the contaminants that will be eluting from the (inlet frits) of the column will get deposited in the detector flow cell or the interface, which is much more difficult to clean. At least for the initial steps of reverse flush, remove the detector from the flow line.

- Both buffers and sugars can be readily dissolved in water and therefore can be removed from the tubing and the column. It will be ideal to provide bit of a high temperature to facilitate the dissolution of these compounds in water, so that they can be easily removed.

- Generally, polar modified and 100% aqueous stable, aromatic hydrophilic phenyl, ion-exclusion, ion-exchange and GFC-SEC phases can be cleaned with 100% HPLC grade water.

- Hydrophobic phases like C8, C18, Phenyl-Hexyl, polymeric reverse phase, GPC-SEC phases and polysaccharide based chiral phases should never be cleaned with 100% water or there will be a high chance of hydrophobic collapse or bonded ligand cleavage.

As reverse phase is the most common chemistry used in chromatography, we will discuss few points on suitable cleaning procedures for RP columns to avoid and resolve high and no pressure issues during analysis.

- Remember, buffers and a few harsh mobile phase additives cause damage in the column, however, the main reason for column deterioration happens because of a variety of complex sample matrices and analytes. Column manufacturers recommend the use of HPLC / Mass Spectrometry grade salts and solvents to prepare mobile phase and also to use 0.2µ membrane filters to filter the mobile phase after preparation, so chances of contamination coming from the mobile phase can be easily avoided or are negligible. It should therefore be reasonable to consider and also essential that you choose your sample diluent (minus any buffers or harsh solvents) for the purpose of column cleaning. Sample diluent can be considered the best solvent to clean your columns.

- Various combinations of water, methanol and ACN should be the first solvents used for column cleaning purpose, depending on the mobile phase and sample diluent compositions.

- For removal of non-polar contaminants from columns, there could be multiple different solvents that can be used, Iso-propyl alcohol (IPA), Methylene Chloride, Hexane and Heptane etc. However, when using these solvents in LC columns, it is recommended to clean the column with Water and Methanol afterwards so that no trace of these strong solvents remained inside the column.

- For protein removal, if initial water and methanol wash doe not help, then a gradient wash with 0.1% TFA in Water and 0.1% TFA in ACN should be used.

For more adamant protein contamination in the stationary phase, Tetrahydrofuran (THF) or Dimethyl sulfoxide (DMSO) can be used as wash solvents. - Other solvents that can effectively remove proteins from columns are Guanidine Hydrochloride and Urea. However, when using these solvents in LC columns, it is recommended to clean the column with Water and Methanol afterwards so that no trace of these solvents remained inside the column.