The split ratio is an important tool with which to maintain forward gas flow through the column and to attenuate the sample mass that enters a GC column. There is a noticeable trend among “split injection” GC methods to apply a higher split ratio when performing an analysis on a column with a narrow internal diameter (ID). A closer look at the fluid dynamics of gas within the GC column will convey the reasons for specific split ratios associated with certain column ID values.

The carrier gas flowing through a GC column will become more viscous as the oven temperature increases. Specifically, the expansion of the gas within the column at higher temperatures will be constrained by the physical column itself. As a result, the gas within the column presents more resistance against any incoming gas that is forced into the column. This resistance becomes more pronounced as the ID of the column decreases, requiring higher pressure at the inlet to maintain forward velocity through the column

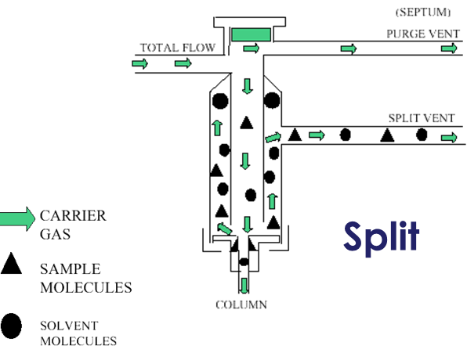

A split injection introduces additional carrier gas into the injection port, such that the gas flowing through the inlet is then “split” between the column and the split vent. If the resistance against flow is too formidable within the column, then a higher proportion of the gas flowing through the inlet will be diverted to the split vent, ultimately leading to an automated shutdown of the GC instrument as forward velocity is lost through the column. A suitable split ratio is needed to introduce a suitable amount of total flow into the injection port to sustain forward velocity through the column throughout a given oven program.

A wide 0.53-mm ID column only needs a split ratio of 2:1 – 5:1, as the wide ID facilitates the forward movement of carrier gas through the column. As such, the pressure at the injection port is rather low. Conversely, a narrow 0.25-mm ID requires a higher split ratio, such that the total carrier gas exerts enough pressure onto the head of the GC column to maintain forward velocity through the column.

Recommended starting split ratios are about 10:1 for a 0.32-mm ID column and 20:1 for a 0.25-mm ID column. Higher split ratios are used to attenuate the total mass of sample that enters the column. There are many reasons to explore different split ratios for a particular method, but always use a split ratio that will generate enough pressure onto the column to maintain forward velocity through the column during an oven temperature program.