Gas chromatography may seem to have a daunting number of variables, but they each complement one another in a manner that becomes intuitive with practice. One such variable is the temperature of the injection port during split and splitless injections of liquid samples. The temperature must certainly be warm enough to assure volatility of the sample diluent and targeted analytes, but may also draw upon other split/splitless parameters when compensating for column limitations.

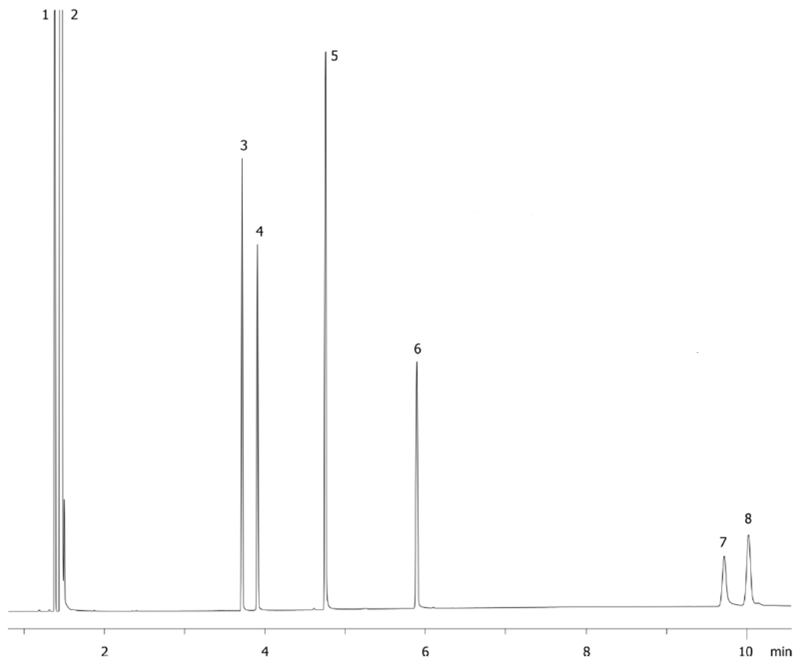

A routine GC method with our ZB-WAXPLUS is the analysis of glycols within water, for which Diethylene Glycol is a common analyte. Water itself has an atmospheric boiling point of 100 °C, while the analyte Diethylene Glycol has an atmospheric boiling point of 245 °C. The ZB-WAXPLUS has an upper temperature limit of 250/260 °C (isothermal/gradient), limiting the injection temperatures that may be used to promote the volatilization of Diethylene Glycol within the injection port. An injection temperature of 225 °C will induce a high vapor pressure within both the water and Diethylene Glycol to facilitate the volatilization of the analyte. The immediate vaporization of the water diluent at 225 °C further facilitates the volatilization of the dissolved analytes. The next consideration is the optimization of the split or splitless injection parameters to take advantage of that brief volatilization of Diethylene Glycol.

The volatilized sample must migrate from the injection port into the column before the Diethylene Glycol begins to condense within the inlet liner of the injection port. A split injection will introduce additional flow of carrier gas through the inlet liner, which will expedite the migration of the volatilized sample onto the column or the split vent. A strict splitless injection would allow the sample to linger within the injection port for 30 – 90 seconds, but a pulsed splitless injection will introduce brief increases of pressure from the carrier gas to usher the volatilized sample onto the column. The chosen temperature of 225 °C will maintain volatility of the Diethylene Glycol long enough for the optimized injection parameters to quickly usher all of the analyte onto the column and split vent.

An optimal temperature for the injection port will work in tandem with the other parameters of the injection methodology. The injection port temperature may have the freedom to reach values at which all of the analytes and sample diluent will confidently volatilize. In other instances, the injection port temperature might be restricted by the GC column limitations. When faced with limitations, choose a temperature that will generate enough volatility among the analytes, such that other parameters of the injection port will consistently usher the sample onto the column.

| GC-FID Conditions | |

|---|---|

| Column | Zebron ZB-WAXPLUS |

| Dimension | 30 meter x 0.25 mm x 0.25 µm |

| Part no. | 7HG-G013-11 |

| Injection | Split 20:1 @ 225 °C, 05. µL; |

| Recommended Liner | Zebron PLUS Single Taper Z-Liner |

| Liner Part no. | AG2-0A13-05 |

| Carrier Gas | Helium @ 3mL/min (constant flow) |

| Oven Program | 80 °C to 180 ° @ 20 °C/min for 20 min |

| Detector | Flame Ionization (FID) @ 250 °C |

| Sample |

|

GC Column Finder Web Tool»

GC Column Finder Web Tool»